Many manufacturing jobs require milling. A hole tool called milling tries to expand the hole’s mouth in turn.

These tasks are significantly faster, simpler, and safer with milling machines than with conventional milling machines. CNC milling reduces human labor in many areas, particularly machine part production and molding. Their potential for mass production is increasing as a result of milling machines with extremely high data processing capabilities. In this article, we will briefly introduce milling machines and share useful information about milling.

What exactly is CNC milling?

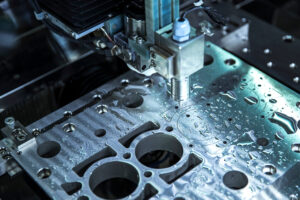

Milling, in its broadest sense, refers to the process of machining a specific work piece using a milling machine. A steel tool known as a milling cutter is used to simultaneously widen a hole’s mouth. Using this tool, you can perform operations on the workpiece to meet a wide range of manufacturing requirements. A wide range of answers for turning and processing was created over the entire course of time. In this unique circumstance, the historical backdrop of processing machines returns seemingly forever. The history of milling machines has also undergone significant transformations thanks to the introduction of electric lathes.

CNC lathes and milling machines are now used in numerous manufacturing processes. For instance, CNC solutions are utilized extensively in numerous industries, including machine manufacturing, the defense sector, aviation, and automotive. Industrial assembly lines and production lines are the most common applications. Numerous other areas of production are made easier by a variety of CNC milling solutions available in a variety of sizes. Milling wood processing solutions, for instance, lead the furniture industry. As of late, the creation of processing cutters in our nation has drawn in extraordinary consideration in numerous areas.

The people who are searching for point-by-point data about the processing system need to know how this interaction happens under PC control. CNC processing activity is a mechanical interaction, truth be told. The materials on the milling machine are drilled by the computer, and it also does other work. The entire situation happens thanks to the approaching orders. The operator offers direction in the appropriate parts. The machine is used by a CNC Milling operator. Approaching orders play out the whole effort. As a result, hand-writing CNC milling machine programs becomes more practical. The machine’s primary commercial function is chip removal. Sub-programs are used for operations other than this one. The sub-programs, in addition to the main programs, provide quick and useful solutions for milling work.

How is CNC Milling Performed?

To complete CNC processing on any workpiece, interfacing the workpiece to the machine is first essential. During this stage, the part’s reference points to the machine are defined. The meaning of the reference points of the part to the machine is given through an accuracy-getting tip called a test. In point of fact, the function of the probe tip is to convey to the machine the workpiece’s raw size and position on the machine. As a result, cutting tools can function flawlessly during milling. The cutting instruments are inserted into a specialized mechanism once the component has settled on the workbench. The magazine is the name of this mechanism. Other mechanical systems that guarantee the workpiece’s movement are now added to CNC milling.

Machines for milling wood

Wood is one of the most common materials for milling. Combinations of woodworking and CNC milling are common in various workshops. CNC milling machines are quick, simple, and extremely accurate. A CNC freesmachine voor hout is useful for woodworking.

Conclusion

We would like to bring this article’s useful information about milling to a close with a brief reminder. In point of fact, CNC milling is a process that necessitates high levels of precision. Accordingly, lessening human mistakes however much as could reasonably be expected is fundamental. We manufacture milling machines specifically for this purpose, which meet a wide range of milling requirements.

Read more:

All about CNC Milling