At Allspeeds Limited, we are always on the lookout to showcase both our adaptability and the established engineering excellence of our team.

When we received a request to take the standard design of our Webtool cutter and adapt it to suit a specific application, we were more than happy to comply.

Recently, we received two such requests from customers in need of modifications to the standard design of our Webtool cutter; both of which had new and extremely high-demand applications in mind for their respective tools.

One of Our Smallest and Lightest Designs to Date

The first request came from a new customer, who was recommended to Allspeeds Limited by an existing user of our cutters. Their requirement concerned a downhole application, which presented unique physical constraints that would prove problematic for our standard Webtool cutter.

For this requirement, our Webtool cutter would need to be modified so as to fit within an internal bore of 8.25” (210mm), while retaining its capacity to slice through a steel wire and two hydraulic lines in a single cut.

Incorporating a double acting cylinder, the resulting cutter had a total weight of less than 6.5kg and measured just over 17 centimetres (or 6.7 inches) in height. This made it one of the smallest tools of its kind our team has ever engineered, which we are proud to have added to our extensive portfolio of specialist wire cutting products.

Understandably, the customer was keen to emphasise how important it was that this small yet critical aspect of the overall tool design was as robust and reliable as possible. This is why they were recommended to Allspeeds Limited by one of our existing customers, having been more than satisfied with our capabilities and expertise.

Backed by more than 30 years’ experience in the design and manufacture of hydraulic cutters for the offshore, subsea, nuclear and defence industries, the Webtool brand is considered the gold standard for these kinds of applications.

As always, the bespoke tool we engineered was extensively tested at our facility in Clayton-le-Moors, Lancashire, prior to being delivered to the customer in Scotland.

A Bespoke Emergency Disconnect Tool

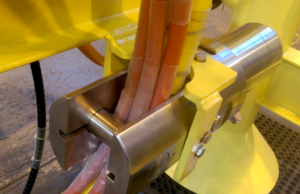

While we were working on this custom design, we received a second request for another modification on the standard Webtool cutter design. In this instance, the customer needed to integrate a powerful yet compact cutter into a winch system, in order to provide an emergency disconnect function.

More specifically, the cutter would need to be able to cut through a fibre rope with copper and fibre optic conductors as quickly as possible in an emergency situation, when the rope would be taut but stationary.

A standard cutter from our existing range was initially offered to the customer, but the decision was subsequently made to create a bespoke cutter to suit their exact requirements. Our team set about putting its knowledge, skills and expertise to the test to come up with the perfect tool.

Following extensive testing and quality verification at our Lancashire facility, the final product was shipped to the customer. Who was, much to our satisfaction, absolutely delighted with the result.

Call Anytime For a Chat…

These are just two examples of dozens of instances where the Allspeeds team has been called on to innovate and engineer something truly unique. Upon request, we are always delighted to take a standard design of cutter and engineer it to suit the specific requirements of the customer’s application.

Our commitment to quality and engineering excellence has earned us an important place across subsea, maritime, renewables and nuclear markets alike. For more information on any of our products or to discuss the development of a bespoke product for a specific application, contact a member of the team at Allspeeds Limited today.

You can also browse our full range of Webtool cutters on our website.

Read more:

Webtool Cutter Development: Bespoke Products for High-Demand Applications